The design of the side channel pump allows for the transfer of liquid-gas mixtures with up to 50% vapor; therefore, eliminating possible air or vapor locking that can occur in other pump designs. A special suction impeller lowers the NPSH requirement for the pump.

The design of the side channel pump allows for the transfer of liquid-gas mixtures with up to 50% vapor; therefore, eliminating possible air or vapor locking that can occur in other pump designs. A special suction impeller lowers the NPSH requirement for the pump.

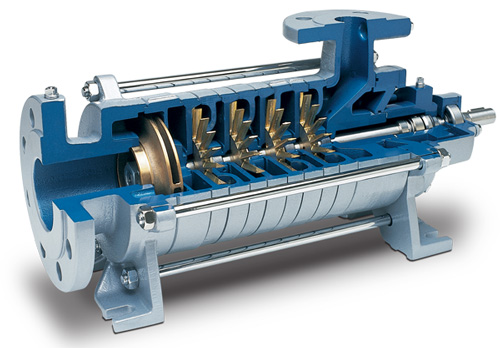

The side-channel pump design is similar to a regenerative turbine in that the impeller makes regenerative passes through the liquid. However, the actual design of the impeller and casing and the principles of operation differ greatly.

The liquid or liquid/vapor mixture enters each stage of the pump through the inlet port. Once the pump is initially filled with liquid, the pump will provide a siphoning effect at the inlet port. The effect is similar to what happens in water ring pumps. The water remaining in the pump casing forms a type of water ring with a free surface. A venturi effect is created by the rotation of the impeller and the free surface of the water, thus pulling the liquid into the casing.

After the liquid is pulled through the inlet port, it is forced to the outer periphery of the impeller blade by centrifugal action. It is through this centrifugal action that the liquid is accelerated and forced into the side channel. The liquid then flows along the semicircular contour of the side channel from the outermost point to the innermost point until once again it is accelerated by the impeller blade. The liquid moves several times between the impeller and the side channel. Thus the rotating impeller makes several regenerative passes until the liquid reaches the outlet port. The speed of the impeller and the centrifugal action impart energy to the liquid through the exchange of momentum, thus allowing the pump to build pressure.

The side channel leads directly to the outlet port. At the outlet port, the main channel ends and a smaller mini channel begins. At the point where the mini-channel ends, there is a small secondary discharge port level with the base of the impeller blades.

As the liquid is forced to the periphery through centrifugal action due to its density, the vapor within the liquid stream tends to remain at the base of the impeller blades since it has a much lower density. The main portion of liquid and possibly some vapor, depending on the mix, is discharged through the outlet port. A small portion of the liquid flow follows the mini-channel and eventually is forced into the area between the impeller blades. The remaining vapor which was not drawn through the outlet port resides at the base of the impeller blades. At the end of the mini channel, as the liquid is forced into the area between the blades, the area between and around the impeller blade is reduced. The liquid between the blades displaces and thus compresses the remaining vapor at the base of the impeller blades. The compressed vapor is then forced through the secondary discharge port where it combines with the liquid discharged through the outlet port as it is pulled into the next stage or discharged from the pump. Thus entrained vapor is moved through each stage of the pump.

Each subsequent stage operates under the same principle. The number of stages can be varied to meet the required discharge head. When multiple stages are required, the relative positions of the stage outlet ports are radially staggered to balance shaft loads.

For information on Corken’s side channel pumps, click on the link below:

Side Channel Pumps for LPG & Ammonia Applications

Refined fuels are petroleum products that are produced from refining processes known as catalytic cracking and fractional distillation. Fractional distillation is a process that uses a heated distillation column to separate a mixture into its individual components. As a mixture is heated in the distillation column, it will eventually reach the boiling point of each component. When the boiling point for a particular component is reached, it will vaporize and separate from the remaining liquid mixture. As the vapor rises, it is separated in another container where it is cooled and condensed back to a liquid.

Refined fuels are petroleum products that are produced from refining processes known as catalytic cracking and fractional distillation. Fractional distillation is a process that uses a heated distillation column to separate a mixture into its individual components. As a mixture is heated in the distillation column, it will eventually reach the boiling point of each component. When the boiling point for a particular component is reached, it will vaporize and separate from the remaining liquid mixture. As the vapor rises, it is separated in another container where it is cooled and condensed back to a liquid.

Corken’s positive displacement sliding-vane pump is known as a Coro-Vane®. Corken offers several models sliding vane pumps for wide range of vapor pressures, differential pressures, capacities, and viscosities.

Corken’s positive displacement sliding-vane pump is known as a Coro-Vane®. Corken offers several models sliding vane pumps for wide range of vapor pressures, differential pressures, capacities, and viscosities. Our regenerative turbine pump is known as a Coro-Flo®. The Coro-Flo regenerative turbine pumps offer a with wide range of differential pressures and capacities for stationary applications.

Our regenerative turbine pump is known as a Coro-Flo®. The Coro-Flo regenerative turbine pumps offer a with wide range of differential pressures and capacities for stationary applications. The side-channel pump is similar to a regenerative turbine pump since the impeller makes regenerative passes through the liquid. However, the actual design of the impeller and casing as well as the the principles of operation differ greatly.

The side-channel pump is similar to a regenerative turbine pump since the impeller makes regenerative passes through the liquid. However, the actual design of the impeller and casing as well as the the principles of operation differ greatly. Corken’s industrial pumps are used in a wide variety of stationary applications such as bulk plant load and unload, vaporizer feeding, NOx reduction, boiler feed, and booster pumps.

Corken’s industrial pumps are used in a wide variety of stationary applications such as bulk plant load and unload, vaporizer feeding, NOx reduction, boiler feed, and booster pumps. Corken’s industrial pumps are used by fuel delivery trucks, tank trucks, mobile (trailer), and tanker ships for bulk load and unloading applications involving refined fuels, solvents, and other light liquids.

Corken’s industrial pumps are used by fuel delivery trucks, tank trucks, mobile (trailer), and tanker ships for bulk load and unloading applications involving refined fuels, solvents, and other light liquids.

The marine industry – generally speaking – encompasses the construction, supply, design, innovation and technology for ships, boats, barges and recreational vessels. The marine industry as it relates to Corken focuses on marine transportation. Corken has a long history of providing loading and unloading solutions for marine transportation. Tanker ships and river barges are the primary marine vessels used to transport liquefied gases, refined fuels and chemicals. Barges are designed for short hauls along the river ways, while tanker ships are designed for longer hauls across the ocean.

The marine industry – generally speaking – encompasses the construction, supply, design, innovation and technology for ships, boats, barges and recreational vessels. The marine industry as it relates to Corken focuses on marine transportation. Corken has a long history of providing loading and unloading solutions for marine transportation. Tanker ships and river barges are the primary marine vessels used to transport liquefied gases, refined fuels and chemicals. Barges are designed for short hauls along the river ways, while tanker ships are designed for longer hauls across the ocean.

The liquid terminals industry is made up of liquid terminal storage companies that store commercial liquids above ground in large bulk tanks known as tank farms. After bulk supplies of refined petroleum products (e.g. gasoline, diesel, fuel oil and kerosene) or chemicals (e.g. solvents, fertilizer, pesticides and acids) are produced, they are stored at a liquid terminal storage facility until distributed for final consumption. Some liquid terminal storage facilities only store chemical or petrochemical products, while other terminals may store an array of bulk liquids such as alcohol, asphalt, fertilizers, animal fats and oils (for cosmetics), vegetable oils (for food products), and molasses.

The liquid terminals industry is made up of liquid terminal storage companies that store commercial liquids above ground in large bulk tanks known as tank farms. After bulk supplies of refined petroleum products (e.g. gasoline, diesel, fuel oil and kerosene) or chemicals (e.g. solvents, fertilizer, pesticides and acids) are produced, they are stored at a liquid terminal storage facility until distributed for final consumption. Some liquid terminal storage facilities only store chemical or petrochemical products, while other terminals may store an array of bulk liquids such as alcohol, asphalt, fertilizers, animal fats and oils (for cosmetics), vegetable oils (for food products), and molasses.

Corken’s reciprocating gas compressors and

Corken’s reciprocating gas compressors and

Liquefied gases are a gaseous compound or mixture that is converted to a liquid when compressed or cooled. They are stored under pressure and transported by a transport trailer, rail car or ship. Depending on the amount of vapor pressure, they are transported and stored in a refrigerated or non-refrigerated container. For example, propane, butane, ammonia, and natural gas can be stored and transported at ambient temperatures. However, liquefied natural gas (LNG), hydrogen and nitrogen have a much higher vapor pressure and must be stored or transported in a refrigerated container.

Liquefied gases are a gaseous compound or mixture that is converted to a liquid when compressed or cooled. They are stored under pressure and transported by a transport trailer, rail car or ship. Depending on the amount of vapor pressure, they are transported and stored in a refrigerated or non-refrigerated container. For example, propane, butane, ammonia, and natural gas can be stored and transported at ambient temperatures. However, liquefied natural gas (LNG), hydrogen and nitrogen have a much higher vapor pressure and must be stored or transported in a refrigerated container.

An oil or natural gas field is an area or region that contains multiple wells designed to extract crude oil and natural gas from below the ground. Typically, natural gas is produced alongside the crude oil production; however, a well that is mainly or all gas is considered a gas well. The life of an oil or gas well is divided into five phases:

An oil or natural gas field is an area or region that contains multiple wells designed to extract crude oil and natural gas from below the ground. Typically, natural gas is produced alongside the crude oil production; however, a well that is mainly or all gas is considered a gas well. The life of an oil or gas well is divided into five phases: The T-style is an oil-free compressor has three sets of V-ring packing per packing rod that form two barriers to external leakage. The barriers are also known as distance pieces. The lower packing set has an adjustable packing screw that is used to maintain maximum sealing performance throughout the life of the packing. Each distance piece has its own line connections that can be padded, purged, or vented separately. This allows you to choose the best method of containment for your application. For added convenience purge kits with all of the accessories needed to control the purging or padding of each distance piece are available.

The T-style is an oil-free compressor has three sets of V-ring packing per packing rod that form two barriers to external leakage. The barriers are also known as distance pieces. The lower packing set has an adjustable packing screw that is used to maintain maximum sealing performance throughout the life of the packing. Each distance piece has its own line connections that can be padded, purged, or vented separately. This allows you to choose the best method of containment for your application. For added convenience purge kits with all of the accessories needed to control the purging or padding of each distance piece are available.