What can it do?

- Mix propane (LPG) with air to provide similar burning values to NG and similar on the Wobbe Index (Gas Composition Match Example 12A)

- Restore lifelines to disaster areas

- Allow normal life to continue during emergency or maintenance

- Provide backup to cogeneration systems

What makes the PA a unique innovation?

- Does not use electricity or external power source

- Using pressure of propane and air

- Easily portable / transportable

- Available in a range of sizes for different projects

- No need to change jets etc. in cookers, heaters…….

- Without any complicated adjustments it produces a stable calorific value.

- The resource is LP gas which is easy to obtain so that we can use PA easily.

- It is convenient to carry and move because it is small and light.

- PA is safe because it automatically stops the resource gas supply if any problems should occur.

- It is easy to control the residual gas in cylinders because PA has a counter for this specific purpose.

Overview

Imagine an earthquake, an act of terrorism, general gas mains maintenance – the gas main to a number of houses, or a hospital, or emergency kitchen has been cut, broken, or just removed for replacement. You can’t use LPG as the jets in the appliances will need changing and you don’t have time for that.

The PA System takes LPG (propane) and mixes it with air producing at the outlet a synthetic gas with the equivalent burning properties and wobbe index as Natural Gas. This system was a key lifeline throughout recent disasters in Japan, but the PA is not just for disaster relief.

General maintenance work can cut-off gas supplies for minutes, hours, days. Disruption to family life, work environments, hospitals and schools can all be kept to a minimum with the temporary replacement of supply using the Ito Corporation PA System.

Cogeneration using Natural Gas to supply both heat and power requires a backup – the PA Systemcan provide this and again uses no electricity.

PA System for CHP – Gas Cogeneration

Operation

This world is full of variety and these diversities include gas. There are wide country differences in mix within LPG and also the blend of Natural Gas in use. The PA requires exact matching of both source and target gas to ensure correct, most efficient, safe and highest quality burning. Please complete the PA System Enquiry Sheet as fully as possible to enable us to carry out this match. Please email back to sales@ito-europe.com or fax to +44(0)1296 658615

Specification Sheets

PA-4 Data Sheet

PA-8 Data Sheet

PA-30 Data Sheet

PA-60 Data Sheet

PA-90 Data Sheet

Flow Chart(PA-4-12A)

Flow Chart(PA-8-12A)

Flow Chart(PA-30-12A)

Certification

There is no European Norme for this type of product we therefore contacted BSI Laboratories who designed a testing regime for the system based upon the individual products conforming to the appropriate EN Standards and also performance and safety testing of the whole system. This testing process has been carried out rigorously throughout this year (2012) and we now have full approval for it’s sale throughout Europe. The individual component regulators have also been certified to EN13785.

WLPGA GTC Innovation Award

GTC Technical Paper Power Point Presentation

LPG Applied Technology for Seismic Hazard Technical Paper

Earthquake Detection protection recovery Oceania Summit Presentation

VIDEO

Flame Quality – Propane vs SNG in Natural Gas Appliance

Case Studies

WLPGA Report – SNG, LPG – Air, Propane – Air

The LPG Opportunity

The World LPG Association recently undertook to produce a report on the opportunities afforded by Synthetic Natural Gas (SNG) Generators, the ITO Europe was asked to contribute and gladly offered the benefit of the Corporations knowledge. Download your copy here

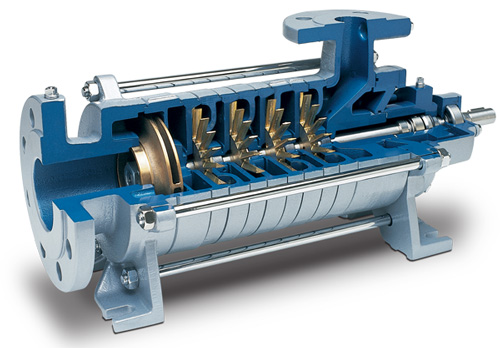

The design of the side channel pump allows for the transfer of liquid-gas mixtures with up to 50% vapor; therefore, eliminating possible air or vapor locking that can occur in other pump designs. A special suction impeller lowers the NPSH requirement for the pump.

The design of the side channel pump allows for the transfer of liquid-gas mixtures with up to 50% vapor; therefore, eliminating possible air or vapor locking that can occur in other pump designs. A special suction impeller lowers the NPSH requirement for the pump. Refined fuels are petroleum products that are produced from refining processes known as catalytic cracking and fractional distillation. Fractional distillation is a process that uses a heated distillation column to separate a mixture into its individual components. As a mixture is heated in the distillation column, it will eventually reach the boiling point of each component. When the boiling point for a particular component is reached, it will vaporize and separate from the remaining liquid mixture. As the vapor rises, it is separated in another container where it is cooled and condensed back to a liquid.

Refined fuels are petroleum products that are produced from refining processes known as catalytic cracking and fractional distillation. Fractional distillation is a process that uses a heated distillation column to separate a mixture into its individual components. As a mixture is heated in the distillation column, it will eventually reach the boiling point of each component. When the boiling point for a particular component is reached, it will vaporize and separate from the remaining liquid mixture. As the vapor rises, it is separated in another container where it is cooled and condensed back to a liquid.

Corken’s positive displacement sliding-vane pump is known as a Coro-Vane®. Corken offers several models sliding vane pumps for wide range of vapor pressures, differential pressures, capacities, and viscosities.

Corken’s positive displacement sliding-vane pump is known as a Coro-Vane®. Corken offers several models sliding vane pumps for wide range of vapor pressures, differential pressures, capacities, and viscosities. Our regenerative turbine pump is known as a Coro-Flo®. The Coro-Flo regenerative turbine pumps offer a with wide range of differential pressures and capacities for stationary applications.

Our regenerative turbine pump is known as a Coro-Flo®. The Coro-Flo regenerative turbine pumps offer a with wide range of differential pressures and capacities for stationary applications. The side-channel pump is similar to a regenerative turbine pump since the impeller makes regenerative passes through the liquid. However, the actual design of the impeller and casing as well as the the principles of operation differ greatly.

The side-channel pump is similar to a regenerative turbine pump since the impeller makes regenerative passes through the liquid. However, the actual design of the impeller and casing as well as the the principles of operation differ greatly. Corken’s industrial pumps are used in a wide variety of stationary applications such as bulk plant load and unload, vaporizer feeding, NOx reduction, boiler feed, and booster pumps.

Corken’s industrial pumps are used in a wide variety of stationary applications such as bulk plant load and unload, vaporizer feeding, NOx reduction, boiler feed, and booster pumps. Corken’s industrial pumps are used by fuel delivery trucks, tank trucks, mobile (trailer), and tanker ships for bulk load and unloading applications involving refined fuels, solvents, and other light liquids.

Corken’s industrial pumps are used by fuel delivery trucks, tank trucks, mobile (trailer), and tanker ships for bulk load and unloading applications involving refined fuels, solvents, and other light liquids.

The marine industry – generally speaking – encompasses the construction, supply, design, innovation and technology for ships, boats, barges and recreational vessels. The marine industry as it relates to Corken focuses on marine transportation. Corken has a long history of providing loading and unloading solutions for marine transportation. Tanker ships and river barges are the primary marine vessels used to transport liquefied gases, refined fuels and chemicals. Barges are designed for short hauls along the river ways, while tanker ships are designed for longer hauls across the ocean.

The marine industry – generally speaking – encompasses the construction, supply, design, innovation and technology for ships, boats, barges and recreational vessels. The marine industry as it relates to Corken focuses on marine transportation. Corken has a long history of providing loading and unloading solutions for marine transportation. Tanker ships and river barges are the primary marine vessels used to transport liquefied gases, refined fuels and chemicals. Barges are designed for short hauls along the river ways, while tanker ships are designed for longer hauls across the ocean.

The liquid terminals industry is made up of liquid terminal storage companies that store commercial liquids above ground in large bulk tanks known as tank farms. After bulk supplies of refined petroleum products (e.g. gasoline, diesel, fuel oil and kerosene) or chemicals (e.g. solvents, fertilizer, pesticides and acids) are produced, they are stored at a liquid terminal storage facility until distributed for final consumption. Some liquid terminal storage facilities only store chemical or petrochemical products, while other terminals may store an array of bulk liquids such as alcohol, asphalt, fertilizers, animal fats and oils (for cosmetics), vegetable oils (for food products), and molasses.

The liquid terminals industry is made up of liquid terminal storage companies that store commercial liquids above ground in large bulk tanks known as tank farms. After bulk supplies of refined petroleum products (e.g. gasoline, diesel, fuel oil and kerosene) or chemicals (e.g. solvents, fertilizer, pesticides and acids) are produced, they are stored at a liquid terminal storage facility until distributed for final consumption. Some liquid terminal storage facilities only store chemical or petrochemical products, while other terminals may store an array of bulk liquids such as alcohol, asphalt, fertilizers, animal fats and oils (for cosmetics), vegetable oils (for food products), and molasses.

Corken’s reciprocating gas compressors and

Corken’s reciprocating gas compressors and

Liquefied gases are a gaseous compound or mixture that is converted to a liquid when compressed or cooled. They are stored under pressure and transported by a transport trailer, rail car or ship. Depending on the amount of vapor pressure, they are transported and stored in a refrigerated or non-refrigerated container. For example, propane, butane, ammonia, and natural gas can be stored and transported at ambient temperatures. However, liquefied natural gas (LNG), hydrogen and nitrogen have a much higher vapor pressure and must be stored or transported in a refrigerated container.

Liquefied gases are a gaseous compound or mixture that is converted to a liquid when compressed or cooled. They are stored under pressure and transported by a transport trailer, rail car or ship. Depending on the amount of vapor pressure, they are transported and stored in a refrigerated or non-refrigerated container. For example, propane, butane, ammonia, and natural gas can be stored and transported at ambient temperatures. However, liquefied natural gas (LNG), hydrogen and nitrogen have a much higher vapor pressure and must be stored or transported in a refrigerated container.